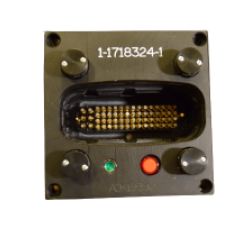

Новый высокоамперный тестовый щуп HSK 5455 на 400.0 A

НАДЕЖНОЕ СОЕДИНЕНИЕ ПЕРЕДАЧИ ВЫСОКИХ ТОКОВ

ТЕСТ КОНТАКТ HSK 5455

ВЫСОКОАМПЕРНЫЙ ТЕСТОВЫЙ ЩУП ДЛЯ ТОКОВ 400.0 A

Тестовые щупы серии HSK 5455 рассчитаны на высокие токи до 400А. Они опционально подходят для использования при функциональном тестировании, передачи сигналов и энергообеспечения.

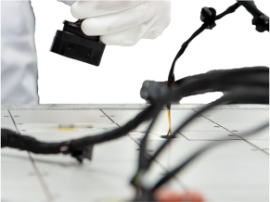

Motor-vehicle manufacturers and subsuppliers set high standards for the contacting incorporated into their test systems. The demands made have, in fact, risen steeply in recent years, particularly in the field of e-mobility. The currents to be tested can, for example, quickly exceed 300.0 A in the case of battery cells and inverters. In addition, vibration and transverse forces can occur during testing or in the energy supply during production.

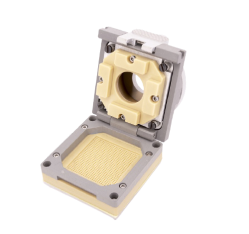

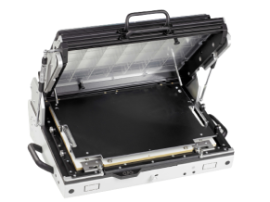

For such conditions, PTR HARTMANN GmbH has now augmented its extensive range of high-current test probes with the new HSK 5455. The HSK 5455 is designed for a continuous current of up to 400.0 A and for use in "end-of-line" (EOL) / function testing. The contact pin is just as ideally suitable for contacting of arresters on pouch and prismatic battery cells, battery modules and battery packs as for contacting of busbars. Despite its compact dimensions, this contact unit is suitable for use in adverse production conditions – transverse forces and vibration cause no problems, nor do uneven contact surfaces. The probe tip is equipped with thirty separately sprung contact pins, assuring extraordinary certainty of contact. This function is supported by the special design of the probe tip, which balances out axial tolerances with a deflection of up to 3.0 °.

The very low contact resistance of ≤ 0.2 mΩ ensures that the voltage drop occurring during testing is kept as low as possible. This is achieved via the use of a continuous plunger, of a large number of highly conductive and readily-contacting probe plungers consisting of a silver alloy, via the use of high-conductivity copper alloys as the base materials and via coating with a tarnish-resistant and abrasion-proof silver alloy.

For quick connection and disconnection, the electrical link at the end of the contact can be made by fitting a cable lug. We recommend the use of a highly flexible conductor for connection, in order not to obstruct movement, since deflection of the probe tip also causes the connecting area to move.